Diesel engines have long relied on two main types of injectors to ensure precise fuel delivery: Solenoid injectors and the more advanced Piezo injectors. Both have been used extensively in 4WDs, trucks, and commercial vehicles, but understanding the differences between them is essential for maintaining vehicle performance, especially in demanding environments like Australia.

In this post, we’ll explore the key differences between Denso Piezo injectors and their older Solenoid counterparts, focusing on how they function, their strengths and weaknesses, and how these differences affect wear, seizure, and overall reliability.

What Are Solenoid Injectors?

Solenoid injectors are one of the most common injector designs. They rely on an electromagnetic coil to open and close the injector, allowing fuel to be sprayed into the engine’s combustion chamber. Here’s a breakdown of the key characteristics of solenoid injectors:

1. Robustness and Reliability

Solenoid injectors have a reputation for being electronically robust. The coil-based design is simple and reliable, making them ideal for older diesel engines that prioritize durability over ultra-fine precision.

2. Susceptibility to Failure

However, solenoid injectors have significant mechanical moving parts that are prone to wear and failure over time. Due to the larger internal components, solenoid injectors often face seizure-related failures, particularly when exposed to fuel contamination or Australia’s harsh driving conditions.

One example of this failure is Toyota Cold Knock, a symptom where cold starts result in unusual knocking sounds. This is often linked to the injector's internal moving parts struggling under stress.

Diagram: Solenoid Injector Moving Components

The diagram clearly shows how the larger number of moving parts in solenoid injectors contributes to their susceptibility to wear and seizure. The greater surface area and inertia create friction and increase the likelihood of failure, particularly in environments where fuel quality is a concern.

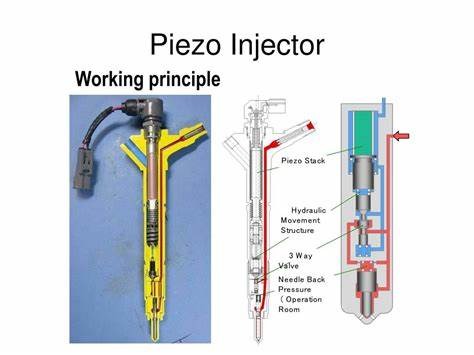

What Are Piezo Injectors?

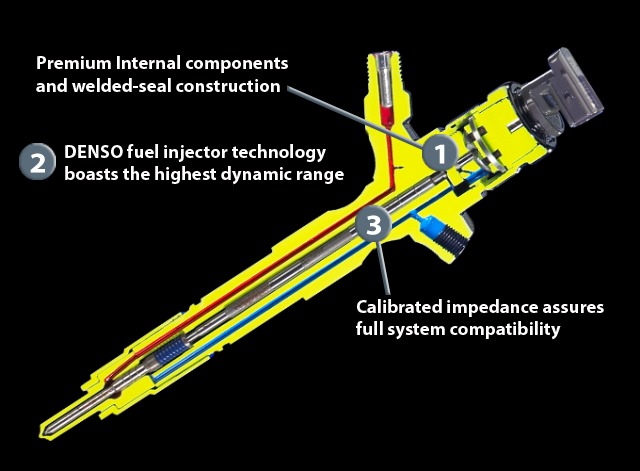

Piezo injectors represent the next generation of diesel fuel delivery systems, relying on piezoelectric materials to achieve rapid and precise injection. Instead of using a magnetic coil, Piezo injectors use a stack of crystals that expand and contract when an electric charge is applied, controlling fuel delivery with incredible precision.

1. Mechanical Robustness

Compared to solenoid injectors, Piezo injectors are mechanically more reliable. The smaller, faster-moving components allow for better control and less internal wear, making them ideal for newer diesel engines, especially in high-pressure common rail systems.

2. Common Issues with Piezo Injectors

Despite their mechanical durability, Piezo injectors aren’t without their problems. In Australia, particularly in Toyota 4WDs, P1238 injector malfunction fault codes are often seen in the 70 series, while the 200 series Land Cruisers have reported excessive smoke due to injector issues. While Denso has addressed some of these problems, newer injector designs have introduced their own challenges.

Diagram: Piezo Injector Moving Components

This diagram illustrates the far fewer moving parts in Piezo injectors compared to solenoids. The result is less friction and wear, making Piezo injectors more durable over time, even in environments with suboptimal fuel quality.

Key Differences Between Solenoid and Piezo Injectors

Now that we’ve covered the basics, let’s compare the two injector types more closely:

1. Precision

Piezo injectors offer far greater precision. They can perform multiple injections per combustion cycle, which improves efficiency, fuel economy, and reduces emissions. In contrast, solenoid injectors are limited in their ability to control injection timing, which makes them less efficient in modern engines.

2. Durability

While solenoid injectors are electronically durable due to their robust coil design, they suffer from mechanical issues, especially in environments like Australia where fuel quality can lead to seizure-related failures. Piezo injectors, on the other hand, are more mechanically robust but can still face problems with software faults or injector malfunctions, particularly in specific vehicle models.

3. Failure Modes

- Solenoid Injectors: Prone to seizure due to larger moving parts and more surface area, which leads to wear. The Toyota Cold Knock is a common issue linked to these injectors.

- Piezo Injectors: Mechanically reliable but can cause P1238 fault codes in the 70 series or excessive smoke in the 200 series, reflecting the delicate balance between mechanical and electronic design.

Real-World Applications: The Toyota 1VD Engine

The Toyota 1VD engine, found in both the 70 series and 200 series Land Cruisers, provides a perfect case study for understanding how these injectors perform in the real world.

Solenoid Injectors in Early 1VD Engines

Early models of the 1VD engine used solenoid injectors, which were robust but eventually developed wear issues over time. Problems like cold knock and injector seizures were common, particularly under harsh conditions or with contaminated fuel.

Piezo Injectors in DPF-Equipped 1VD Engines

In later models, Denso introduced Piezo injectors, particularly in the 200 series Land Cruiser with DPF (Diesel Particulate Filter) systems. These injectors delivered more precise fuel control, but they also introduced new issues like excessive smoke and error codes, which have required ongoing attention.

Maintenance and Replacement Considerations

Maintaining your injectors is critical for keeping your vehicle running smoothly. Here are a few tips to ensure both solenoid and Piezo injectors last as long as possible:

- For Solenoid Injectors: Be aware of cold start knocking or rough idling, which can be early signs of wear. Regularly check for injector wear or contamination, especially in high-mileage vehicles.

- For Piezo Injectors: Look out for excessive smoke or fault codes like P1238, which can indicate injector issues. Despite their mechanical durability, Piezo injectors require regular software updates and inspections to ensure optimal performance.

If you’re experiencing injector problems or are looking to replace your injectors, Diesel Geeks offers a full range of genuine Denso injectors, including both solenoid and Piezo options, depending on your vehicle’s needs.

Conclusion

Both Denso solenoid and Piezo injectors have their place in the world of diesel performance, each with its strengths and weaknesses. Solenoid injectors, while reliable electronically, face issues with wear and seizure due to their complex mechanical design. On the other hand, Piezo injectors are more advanced but come with their own set of challenges, particularly in newer models with specific failure modes.

At Diesel Geeks, we offer expert advice and top-quality products for both injector types, ensuring you get the best performance and longevity from your diesel engine. Contact us today to learn more about which injector is right for your vehicle.