Common issues like cold knock and wear due to high-pressure erosion can cause significant engine damage if left unchecked. This guide will take you through the steps to diagnose these problems accurately using detailed injector readings and a reliable scan tool.

Understanding Injector Issues

Cold Knock and Individual Cylinder Corrections:

The individual cylinder corrections at idle provide a vital insight into the health of your injectors when the engine is cold. Ideally, these corrections should be within +/- 3.0 mm³ per stroke. Noticing discrepancies greater than +/- 2.0 mm³ can indicate the onset of cold knock—a serious issue that mimics the sound of a failing bottom-end bearing but only occurs when the engine is cold.

However, these numbers might return to normal levels when the engine warms up. It's crucial to understand that normal warm readings don't necessarily mean the injectors are healthy. This symptom misleads many into ignoring potential cold knock issues.

Wear and Total Injection Volume:

As injectors wear, their efficiency decreases, which is evident from the total injection volume at warm idle. New or healthy injectors will typically display readings between 5.5 and 6.5 mm³ per stroke. When these figures rise beyond 9.5 mm³, consider inspecting the injectors for potential replacement. We've observed worn injectors displaying as much as 18 mm³ per stroke, clearly indicating severe wear often due to foreign particles scoring the injector internals.

Technical Tools for Diagnosing

To accurately diagnose these conditions, you'll need a workshop-level scan tool or Techstream 2 connected to your laptop. Here’s how to use these tools effectively:

- Connect the Scan Tool: Start by connecting your scan tool to the vehicle’s diagnostic port. Power up both the tool and your laptop, ensuring they are properly communicating with the vehicle’s ECU.

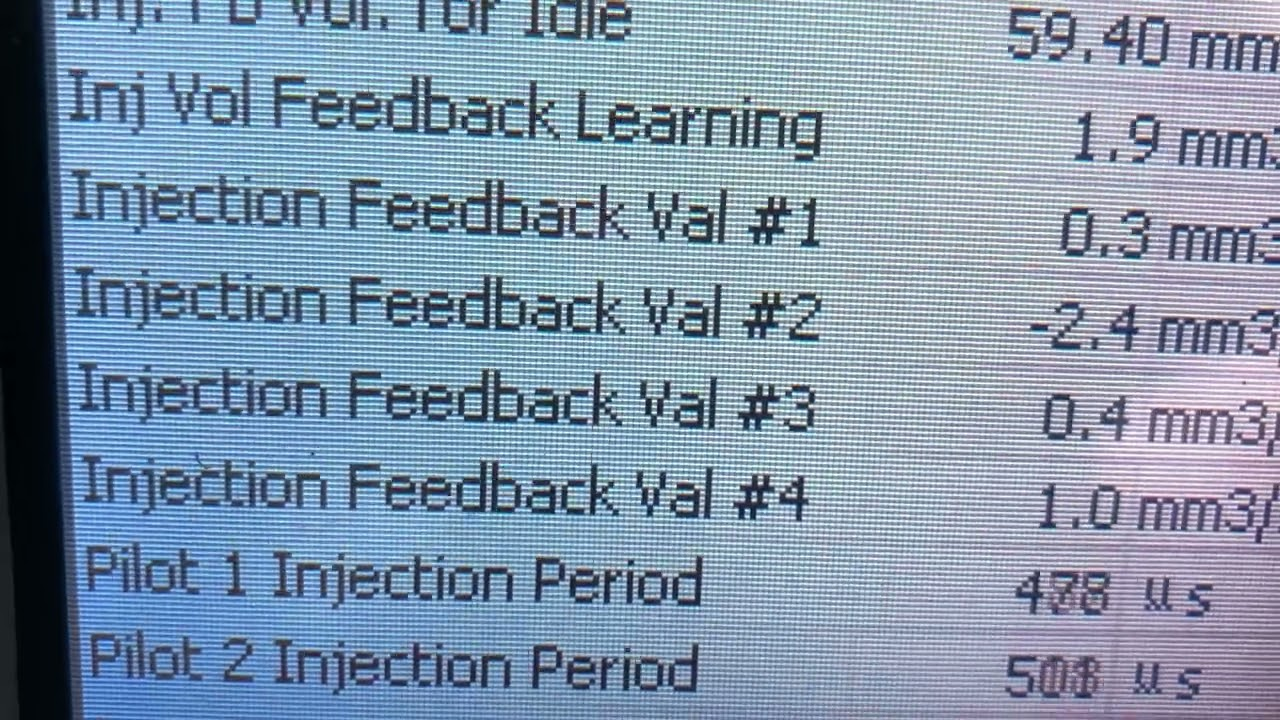

- Reading Injector Values: Navigate to the injector diagnostics section. Look for real-time data concerning individual cylinder corrections and total injection volume. Take note of these values both when the engine is cold and after it has warmed up.

- Interpreting Data: Compare your readings against the typical values mentioned earlier. Values outside the normal range suggest it's time for a more thorough inspection or possible injector replacement.

(Example screen showing injector readings)

Visual Guide to Injector Parts

Understanding the parts of an injector can help you better diagnose issues. Below is a simple diagram illustrating the main components of a 1KD injector and common areas where wear and tear occur.

(Keep diagrams simple and straightforward for easy understanding)

Related Reading for Comprehensive Care

Expand your knowledge and ensure comprehensive care for your 1KD engine by exploring these related articles:

- Everything You Need to Know About Toyota Suction Control Valves

- Toyota Cold Knock Explained

- What are Denso Codes and How They Work

- What Changes with Toyota Updated Injectors Over Time

Conclusion

Diagnosing injector issues early can save you from costly repairs and maintain the optimal performance of your 1KD engine. Use the guidelines and tools recommended in this post to keep your engine running smoothly. Don't hesitate to check out our other technical posts or contact Diesel Geeks for support and guidance.

Toyota Hilux Injectors

- $264.00Add to cart

- $313.50Add to cart

- $880.00Add to cart

- $126.50Add to cart

- $478.50Add to cart

- $499.40Add to cart

- $499.40Add to cart

- $478.50Add to cart